The photographs in this article are from an S2, however

the calipers and techniques are identical to an S1.

Thanks to Richard Gilmour for the photographs.

WARNING : Unless you are confident you know what

you are doing, have the correct tools, and understand the implications

of making a mistake don't work on the braking system of your car.

No Liability can be accepted should you make a

mistake whilst working on your brake system.

Front

Jack up the side of the car using the central jacking

point, having first loosened the wheel nuts and turn the steering to

ease access to the caliper, remove the wheel.

Ensure your safety by making sure the car cannot

fall and that you are not relying on a hydraulic jack to hold the weight

of the car.

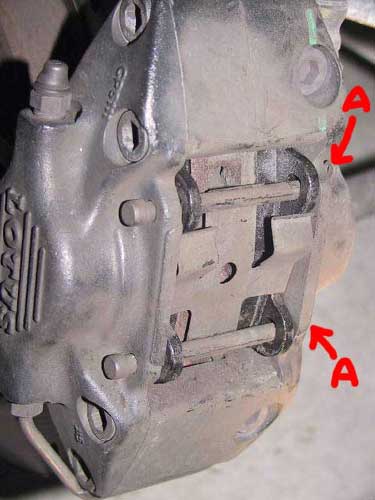

Remove the R clips from the inside of the two pad retaining

pins (A in the picture below)

withdraw the pad retaining pins (B in the picure below)

from the caliper, be carefull to hold onto the pad anti-rattle spring

(and note it's orientation) otherwise it will spring off and disappear

;-).

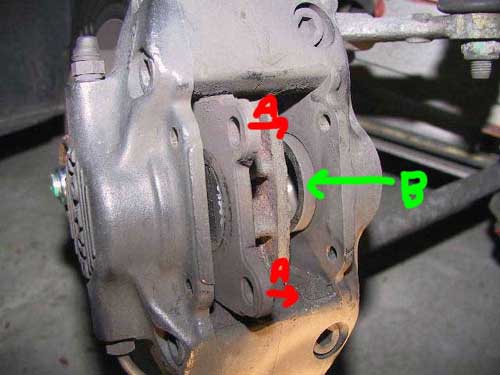

Now remove the pads by pulling them in the direction marked

(A in the picture below)

The caliper pistons must now be pushed into the caliper

body, there are two pistons (the inner one marked B in the picture above).

It should be possible to push the pistons into the caliper

by hard finger pressure alone, however this takes some grunt and persistence.

It may be necessary to improvise something to push the pistons but you

must be very carefull to push the piston squarely into the piston bore

otherwise you can damage the piston or bore or both. When fully pushed

in the pistons will be flush with the caliper inner face.

Insert the new pads in the same orientation as the old

pads, replace the pad retaining pins and R clips and replace the wheel.

That sounded fast, but re-assembly is the simple reversal of disassembly

at this point, if you are all done make sure to close the brake fluid

reservoir.

Some points of note, You MUST pump the brake pedal until

it is firm BEFORE moving the car, this allows the caliper pistons to

self adjust to the correct position with the new pads.

Carefully smearing coopergrease on the piston facing side

of the pad (NOT the surface touching the disk) can help stop squealing.

However this is one of those religious debates which some people agree

with and some violently disagree with, whatever works for you is fine,

I always use coppergrease and my brakes never squeal.

DOUBLE CHECK everything, TWICE,

the brakes are very simple, but also absolutely critical, your and others

lives depend on them, if you are unsure about what you are doing, leave

it to a specialist. Better broke than dead.

Jack up the side of the car using the central jacking

point, having first loosened the wheel nuts and remove the wheel. You

must ensure the handbrake is off, so alternative measures must be taken

to prevent the car from moving whilst jacked.

Ensure your safety by making sure the car cannot

fall and that you are not relying on a hydraulic jack to hold the weight

of the car.

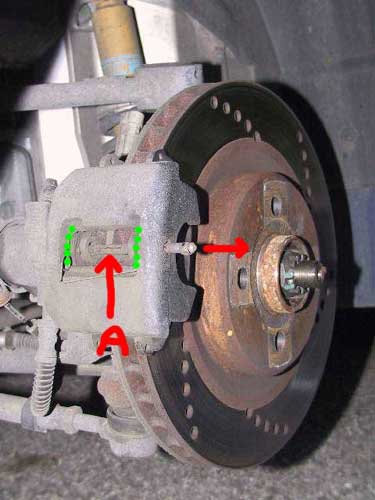

Note the positions of the pad anti-rattle springs, there

are two of them fitted (the green dots on the picture above show their

locations), Remove the pad retaining pin (A in the picture above) from

the caiper by using an appropriately sized punch to push it ou of the

caliper in the direction shown. Make sure the ani-rattle springs don't

disappear into hyperspace when you remove the retaining pin.

Remove the caliper upper retaining bolt from the back

of the caliper, this will ultimately allow the caliper to rotate about

the lower caliper retaining bolt (have a look behind the caliper to

see both before you start)

Remove the outer pad in the direction shown above, it

may be necessary to use a light punch to move the pad initially.

Rotate the caliper towards the rear of the car after removing

the inner pad to gain access to the single piston. Be carefull not to

damage the handbrake cable at this point, so not force the caliper.

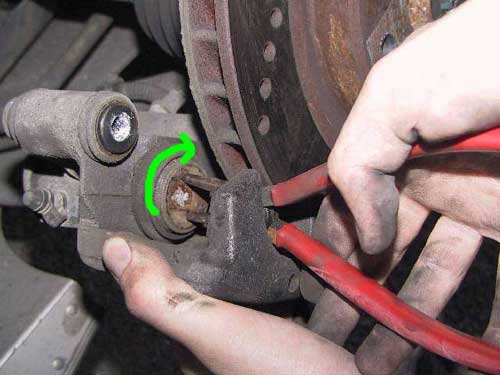

To push the piston back into the caliper you must turn

it as it is being pushed, if you do not do this the piston will not

push back into the caliper. Again the piston will be flush with the

caliper inner face when it is fully retracted.

Be Carefull not to damage the piston seals if you use

long nosed pliers as shown above as they can easily slip and cut the

seal. You may wish to buy a proper piston wind-back tool for this job

if you are not familiar.

Some points of note, You MUST pump the brake pedal until

it is firm BEFORE moving the car, this allows the caliper pistons to

self adjust to the correct position with the new pads. Verify that the

handbrake functions correctly.

Again, as of this point re-assembly is a simple reversal

of disassembly, and coppergrease may or may not be used depending on

your religion,

DOUBLE CHECK everything, TWICE,

the brakes are very simple, but also absolutely critical, your and others

lives depend on them, if you are unsure about what you are doing, leave

it to a specialist. Better broke than dead.

Disclaimer : All information is supplied as a guide only.

No Guarantee as to its reliability can be issued.

You use this information entirely at your own risk.

No Reproduction or Reuse without prior written consent.